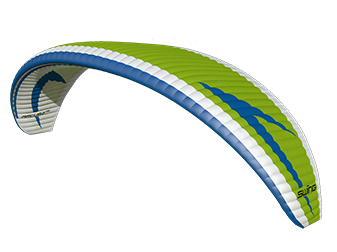

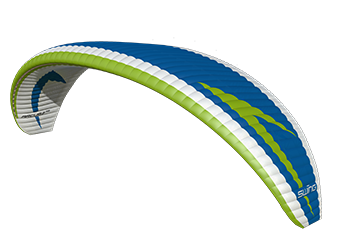

Swing

Arcus 2 RS

Arcus 2 RS

Couldn't load pickup availability

The ARCUS 2 RS is based on the very successful and proven NYOS RS. With a little less aspect ratio, a new, resilient material mix and a lot of attention to detail, we have completely revised the design and adapted it to pilots who feel most comfortable in the mid-B segment.

Achieving new levels of flying without overreaching yourself – that was precisely our goal in developing the ARCUS 2 RS.

The ARCUS 2 RS is based on the very successful and proven NYOS RS. With a little less aspect ratio, a new, resilient material mix and a lot of attention to detail, we have completely revised the design and adapted it to pilots who feel most comfortable in the mid-B segment. With a full 57 cells, the elegant wing already visually underlines its performance claim, but the compact flight feeling immediately conveys familiarity with a high feel-good factor and promises pure flying fun.

Who is the ARCUS 2 RS for?

Ambitious pilots who want to enter the B-class, will feel just as comfortable under the ARCUS 2 RS as long-time licence holders and returnees from higher classes, for whom a high degree of passive safety with appealing performance is important.

You will feel the genes of its big brother, the NYOS RS, after the first revolutions in a thermal. Thanks to its extremely precise and direct handling, the ARCUS 2 RS takes you playfully to the top before giving you a glimpse of its performance potential on the transition. The stable canopy and optimised RAST system give you the confidence to try new things and fly further than ever before.

Features

Features

• RAST; For maximum control. On paragliders with RAST® the canopy is divided into different internal pressurised sections by one or more fabric panels, some with valves running crossways to the direction of flight. This makes it possible to influence the air flows within the canopy.

With RAST, the air equalisation flows within the paraglider canopy can be regulated through defined openings. This applies both when filling, (during take-off) and when emptying. In the case of pressure loss, e.g. caused by canopy collapse in turbulent air, the relative internal pressure of the CORE section increases, while the BUFFER section absorbs the introduced energy by deformation. Furthermore, RAST can be used as an additional support to the leading and trailing edge, which has a positive effect on flight comfort. As RAST connects the ribs over the entire profile height, the construction has a stiffening effect and reinforcements and/or stiffening elements can be saved or even completely replaced by this special construction method.

In the ARCUS 2 RS, RAST has been optimised for the following characteristics: Smooth flight and maximum control in demanding conditions

• High canopy stability even at maximum speed

Nitinol Wires - For maximum profile stability and minimum weight; Nitinol is a high strength, temperature and corrosion resistant, shape-memory alloy. The name Nitinol is an acronym for Nickel Titanium Naval Ordnance Laboratory. SWING has long been one of the first paraglider manufacturers to use this material, mainly known for its use in medical technology, as a nose reinforcement in paraglider construction.

For paraglider models where weight reduction is not the top priority, we have inserted the Nitinol reinforcements into nylon tubes. This increases the cross-section – and thus the contact area for the upper sail material – without having to forego the positive properties (resistance to buckling, length and shape stability) of the memory material. This leads to an improvement in the longevity of the glider.

• Mini-ribs - For a homogenous trailing edge; Ballooning at the trailing edge of a paraglider has a significant influence on performance, control pressure and handling. Mini-ribs halve the cell spacing in this area and thus reduce ballooning to give a uniform trailing edge.

The highlight: The seams of the mini-ribs run on the inside of the upper sail, so that even during launches on unfavourable ground, no threads can get caught on the ground and be pulled out.

• 3D shaping - For optimised aerodynamics; The targeted control of tension by 3D shaping at the leading edge of the upper sail has become standard in paraglider construction. This is in order to make the airflow-relevant areas as crease-free as possible. Depending on the model, 3D shaping is either single or double in its construction.

We have supplemented the standard shaping with another 3D shaping at the leading edge to optimise the aerodynamic effect of the mini-ribs.

• Coloured riser connections - for minimised risk of confusion; To avoid mistakes when attaching the harness, the attachment loops are colour-coded. This means you can see at a glance whether the risers are correctly attached to the harness.

Specifications

Specifications

• Sizes; XS*, S, M, L, XL

• LTF homologation; B

• CEN homologation; B

• Permissible weight range (kg) min./max. incl. equipment; 58-78, 75-95, 85-105, 95-115, 105-140

• Recommended weight range (kg) min./max. incl. equipment; 60-78, 80-95, 92-105, 102-115, 115-135

• Cells; 57

• Wing area (m²); 22.0, 25.0, 26.8, 29, 33

• Projected wing area (m²); 18.9, 21.5, 23.1, 25, 28.4

• Wing span (m); 10.9, 11.6, 12, 12.5, 13.3

• Projected wing span (m); 8.9, 9.1, 9.7, 10.0, 10.5

• Aspect ratio; 5.4

• Projected aspect ratio; 4.2

• Glider weight (kg); 4.4, 4.8, 5.1, 5.4, 5.8

• Min. sink rate** (m/s); 1.0

• Max. speed** (km/h); 50±2

• Trim speed** (km/h); 38±1

*In development

**The performance data depend on the wing loading, the atmospheric conditions and the harness used, as well as the pilot position.

Share